Are You Moving Live Lab CTUs (Controlled Temperature Units such as Fridges or Freezers)

February 2025

The Top 4 Key Factors for a Successful Move

Moving lab equipment, especially systems such as Controlled Temperature Units (CTUs), needs careful planning and attention to detail. There are four key factors to consider for a successful move to ensure that the process goes smoothly, and that the samples and equipment remain safe and operational. Below highlights some important aspects to address, including electrical and monitoring considerations, move path/logistics, securing your samples, and ensuring a proper shutdown of the equipment.

Below are four important factors to keep in mind before beginning your move.

#1 Electrical and Monitoring Considerations

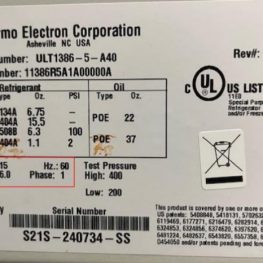

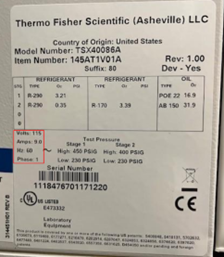

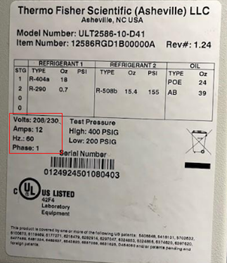

As part of your early lab planning stages, make sure all CTUs are properly inventoried. During this inventory phase, it’s important to record the inventory ID number/serial number, dimensions, weight, and electrical nameplate data. All appliances are required, under NEC422, to have a nameplate that provides key information such as voltage, frequency, phases, and sometimes amperage.

While this nameplate won’t specify the plug type, the following information should be helpful if the unit cannot be unplugged for verification.

- Single Phase, 115V units with an amp rating of less than 15A will use a NEMA 5-15P plug.

- Single Phase, 115V units with an amp rating between 15A < x < 20A will use a NEMA 5-20P plug.

- Single Phase, 208V/230V units with an amp rating less than 15A will use a NEMA 6-15P plug.

- Single Phase, 208V/230V units with an amp rating between 15A < x < 20A will use a NEMA 6-20P plug.

Additional items to consider:

Additional items to consider:

- Does the CTU require more than one receptacle?

- Is there secondary monitoring in place? If so, does it require an additional receptacle? Is it connected via Ethernet or Wi-Fi? Is the network in the new location set up to accept these units (i.e. active network ports or firewall access?)

#2 Move Path/Logistics – Before the mover arrives on site, make sure to consider the following:

- Is the unit on wheels?

- Will the units fit below and through all the door frames along the travel path?

- Do you have direct elevator access to the loading dock?

#3 Secure Your Samples

- The materials inside the CTU are more than likely to get jostled during the move, especially if the unit needs to be tipped or lifted to clear door frames or other obstructions.

- The best practice is to secure items to their racks or lock the sample doors. Packing paper can also be used though care should be taken to avoid airflow restrictions if samples are traveling long distances.

- For samples in glass containers, move them to the bottom of the CTU prior to moving to prevent potential damage.

#4 Ensure Proper Shutdown

Simply unplugging your CTU is not sufficient. An improper shutdown can lead to CTU failure and a potentially chaotic situation. Most CTUs have either a key, toggle switch, or touchscreen that should be used to properly turn off the unit before moving it.

By carefully evaluating electrical specifications, moving path logistics, sample security, and proper shutdown procedures, you can minimize the risk of damage or disruptions during your move. Taking the time to plan and prepare will help ensure that your CTU is ready to operate at full capacity once it reaches its new location. With the right preparation, your move can be efficient, safe, and successful.

Chris has over 10 years of experience in construction management and owner’s project management. He has experience managing projects from design, construction administration, and close out. Most notably Chris has spent the last four years working on the Sanofi account with projects ranging from MEP installations, startups, and commissioning as well as new lab fit outs. Prior to joining Northstar, Chris worked on a variety of projects in pharmaceutical and life science sectors.